Why Aluminum Awnings Fell Out Of Favor

Aluminum awnings are once again becoming the most popular choice for building canopies. After losing popularity for decades technological advancements in the production of aluminum, more customization options, and a return to a classic design aesthetic has made aluminum awnings the top choice of architects and builders again.

When aluminum awnings were introduced into commercial construction in the 1930’s they quickly became the industry standard. The sleek modern look of aluminum awnings and the affordability of the material made them a popular design element for businesses, schools, and hospitals, and other commercial buildings.

But in the mid-to-late 20th century aluminum awnings fell out of style in favor of fabric awnings. Fabric awnings were seen as more inviting to the public.

They expressed a casual vibe that fit the design aesthetics of the era. Fabric awnings also made it easy for businesses to experiment with color, logos, and other branding element at an affordable price. Some of the other reasons why fabric awnings because the popular choice include:

Changing Architectural Trends

In the later part of the 20th century commercial architecture shifted to a modernist architecture style with minimalist design. Aluminum awnings were viewed as old-fashioned and out of touch.

There was also a design shift to more open spaces and emphasis on natural light for commercial buildings. Design elements like curtain walls, more open facades, and unobstructed storefronts became trendy.

Cost & Flexibility

As construction costs increased architects and builders looked for ways to save money on projects without sacrificing the key elements of the build. Using fabric awnings instead of metal was one way to cut costs because fabric awnings were cheaper to produce and cheaper to replace over time. It was also less expensive to customize fabric awnings with branding elements like logos and colors.

Energy Efficiency Concerns

The aluminum awnings used in the last century weren’t as durable or as efficient as aluminum awnings are today. They would absorb and radiate heat, making interior spaces extremely warm even in mild weather. Fabric awnings were UV resistant and heat reflective, so they were more efficient.

Maintenance & Durability

When aluminum awnings were in favor manufacturers often used cheap steel frames with soda-can thin aluminum panels to create custom awnings fast. These metal awnings were prone to denting and corrosion, especially in coastal areas or areas with extremely wet climates.

Fabric was a good alternative to poorly made metal awnings at the time because fabric awnings had weather-resistant coatings and required less maintenance. If they did become damaged, fabric awnings were cheaper to replace.

Building Codes

In some areas changes in local building codes rewarded businesses that chose fabric awnings over metal awnings for safety and space efficiency.

Innovation Leads To A Re-Birth Of Aluminum Awnings

Design trends are always changing, and after many years of being the industry choice fabric awnings are waning in popularity. Over the years the weather has gotten more extreme, and fabric awnings just can’t stand up to the intense rays of the sun, additional rain and snow, and an increase in high winds that can cause fabric to rip.

Fabric awnings require a lot of maintenance. Without regular cleaning they are prone to mold growth and they can fade quite quickly in areas that get a lot sun. When fabric awnings become damaged or faded they need to be replaced which can be expensive and require businesses to close while new awnings are installed. Higher costs, lots of maintenance, and lost revenue during replacement make fabric awnings unpopular with business owners. Aluminum awnings, which have better durability, more customization options, and easier installation than in the past have become a great alternative to fabric awnings.

Aluminum Awnings Get A Modern Upgrade

More precise manufacturing techniques, improved coatings for strength, corrosion-resistance, and durability and the ability to customize the look of aluminum to match different design styles are making aluminum awnings the choice of industry experts again.

Precision Manufacturing & Advanced Fabrication

Thanks to modern technology and industry innovations manufacturers are able to create precision-cut aluminum panels that can be installed quickly to save money without sacrificing quality or aesthetic value. Some of the industry advancements that make this possible are:

- Laser cutting & CNC machining – Modern manufacturing processes allow for highly precise cuts and intricate designs, making it easy to customize designs quickly and affordably.

- Stronger, lighter aluminum alloys – Improved metallurgy led to the creation of aluminum that is both lightweight and structurally stronger than aluminum used in the past. That means aluminum awning are lighter to transport and easier to install without sacrificing durability.

- Seamless construction options –The way that awning panels are produced means fewer seams and joints. Fewer seams and joints mean that modern aluminum awnings have better strength, fewer weak points, and a much more modern and sophisticated appearance.

Improved Coatings For Strength & Corrosion Resistance

Modern coatings fixed several of the problems that led to the downturn in the popularity of aluminum awnings in the last century. Today’s high-strength coating options like these make aluminum a more durable choice than fabric awnings:

- Powder coating technology – More durable than traditional paint, powder-coated finishes resist chipping, peeling, and fading from extreme weather. With temperatures rising and extreme weather becoming the norm it’s essential that buildings have awnings that can withstand excessive heat, cold, and storms.

- Anodized aluminum finishes – Anodize aluminum goes through a chemical process that increases corrosion resistance. Buildings in coastal areas or areas that now prone to heavy rain, extreme storms, or flooding need to have awnings that are as corrosion-resistant as possible.

- Reflective and heat-resistant coatings – Specialized finishes for aluminum panels can help improve energy efficiency by deflecting more solar heat away from buildings.

Enhanced Durability & Longevity

Better durability and longevity also are contributing to the resurgence in popularity of aluminum awnings. Steel frameworks covered by tin-can panels are a thing of the past. Modern aluminum awnings have:

- Stronger frame construction – These days aluminum panels are designed to withstand even the most severe weather with innovative structural enhancements that reduce bending or warping over time. Less maintenance is needed because of the enhanced strength of today’s aluminum awnings.

- Reinforced brackets and supports – Modern aluminum awnings have better mounting systems that allow for better load distribution. That makes the awnings able withstand heavy snowfall, large amounts of rain, and intense winds.

- Integrated drainage systems – For buildings in coastal climates or areas prone to extreme storms aluminum awnings with built-in drainage features prevent water accumulation which could damage the metal over time.

Design & Customization Options

Aluminum awnings now have the kind of design range that made fabric awnings popular in the last century. Whether a commercial design calls for a sleek modern awning design, a retro mid-century modern look, or a vintage style awning perfect for recreating the look of a historical building innovations like these give architects a huge range of options for creating the perfect complement to their aesthetic:

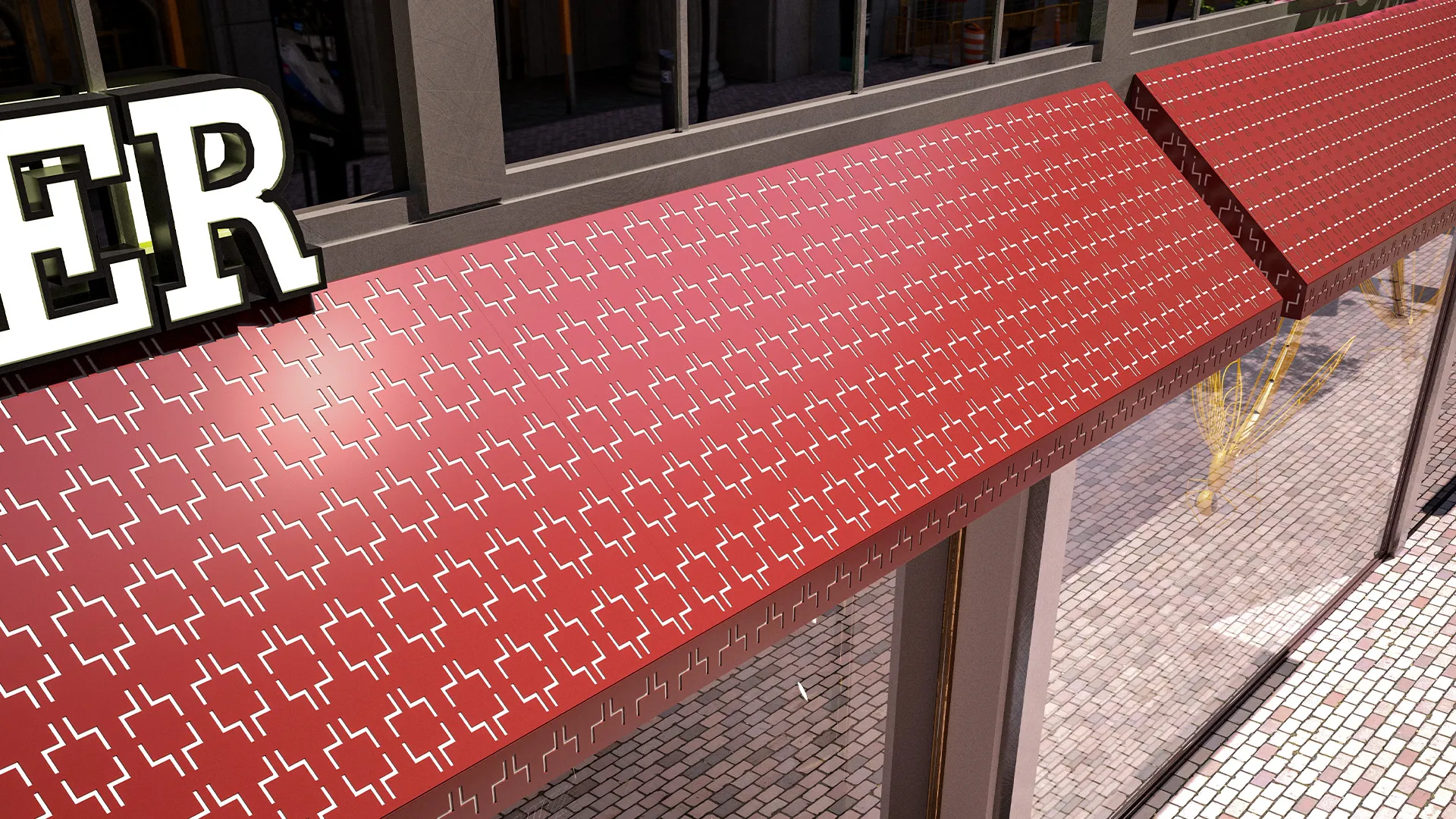

- Expanded color and texture options – High-quality coatings for aluminum make a variety of finishes possible for awnings. From classic metallic to woodgrain textures that mimic natural materials awnings can be made to fit any design.

- Modular & retractable designs – Many manufacturers now offer modular aluminum awnings that can be reconfigured or retracted for more flexibility and to better meet local building codes that have rules about space efficiency or safety.

- Architectural compatibility – Custom shapes and patterns make aluminum awnings adaptable to modern, industrial, and even traditional architectural styles.

With these advancements, aluminum awnings are no longer just functional, they are a design statement. Their increased strength, longevity, and adaptability make them an attractive, cost-effective choice for commercial buildings looking for both style and performance.

Find The Right Aluminum Awning For Your Next Project

Browse through Umbra aluminum awning projects to see the stylish, durable, and modern options available for your next project. You can also contact Structureworks to find out more about Umbra metal awnings and the customization options available for commercial construction projects.